Eco-Conscious Guide to Precious Metal Recycling

Were you aware that electronic waste throws away over $60 billion of precious metals annually? This staggering figure underlines the critical role of precious metal recycling. It’s not just good for our economy but also for the environment. When we recover gold, silver, platinum, and palladium, we reduce pollution and conserve resources.

Firms like Dongsheng Metal Trading spearhead the movement toward greener recycling. They make sure those precious metals get reused rather than landfilled. This precious metal recycler approach is key to eco-friendly recycling and sustainable practices.

Important Lessons

- Over $60 billion in precious metals is disposed of in electronic waste annually.

- Precious metal recycling reduces environmental impact and conserves resources.

- Key precious metals are gold, silver, platinum, and palladium.

- Green recycling methods are essential for a sustainable future.

- Firms such as Dongsheng Metal Trading focus on precious metal recovery.

Understanding Precious Metals and Their Value

Rare metallic elements known as precious metals attract both investors and manufacturers. Examples include gold, silver, platinum, and palladium, each prized for special traits. These include electrical conductivity, corrosion resistance, and substantial rarity. Extracting and refining them uses up huge resources, so recycling becomes critical.

Market demand and each metal’s properties drive its value. Recovering metals is key to keeping the supply chain alive. It also reduces environmental impacts associated with mining activities. Advanced recycling can bring metals back to their initial quality. Such efforts save limited resources and create economic gains.

Precious Metals Explained

Unique features make precious metals ideal for many uses. Scarcity plus special properties drive their economic importance. Notable examples are:

- Au: Admired for its luster and low corrosion.

- Ag: Recognized for its versatility and high conductivity.

- Pt: Celebrated for its durability and catalytic properties.

- Pd: Increasingly popular in automotive and electronic applications.

Benefits of Precious Metal Recycling

Recovering precious metals plays a crucial role in sustainability. It helps conserve these finite resources and significantly reduces the ecological footprint tied to traditional mining. Key benefits include:

- Reduction of environmental degradation caused by mining operations.

- Lower energy consumption compared to extracting new metals from the earth.

- Feeding materials back into the production loop.

- Opportunity for profit by recovering valuable metals.

Why Precious Metal Recycling Matters

Metal recycling brings both green and economic gains. Highlighting these advantages is key to reducing our ecological footprint. Additionally, it fuels market growth and resilience.

Eco Advantages

Green gains from metal recycling are huge. By reclaiming metals from discarded electronics and industrial scrap, we cut down on landfill waste. This reduces the need for new mining, conserving natural resources.

This approach minimizes the harmful effects of mining, such as habitat destruction and pollution. A focus on metal recovery moves us toward real sustainability.

Financial Gains

Economic upsides of recycling stand out equally. Recovering metals cuts production expenses. This allows industries to use reclaimed metals instead of new ones.

This shift creates jobs in recycling facilities and boosts market stability as demand for recycled metals grows. By leveraging these economic advantages, businesses can improve their profitability. They also contribute to a greener economy.

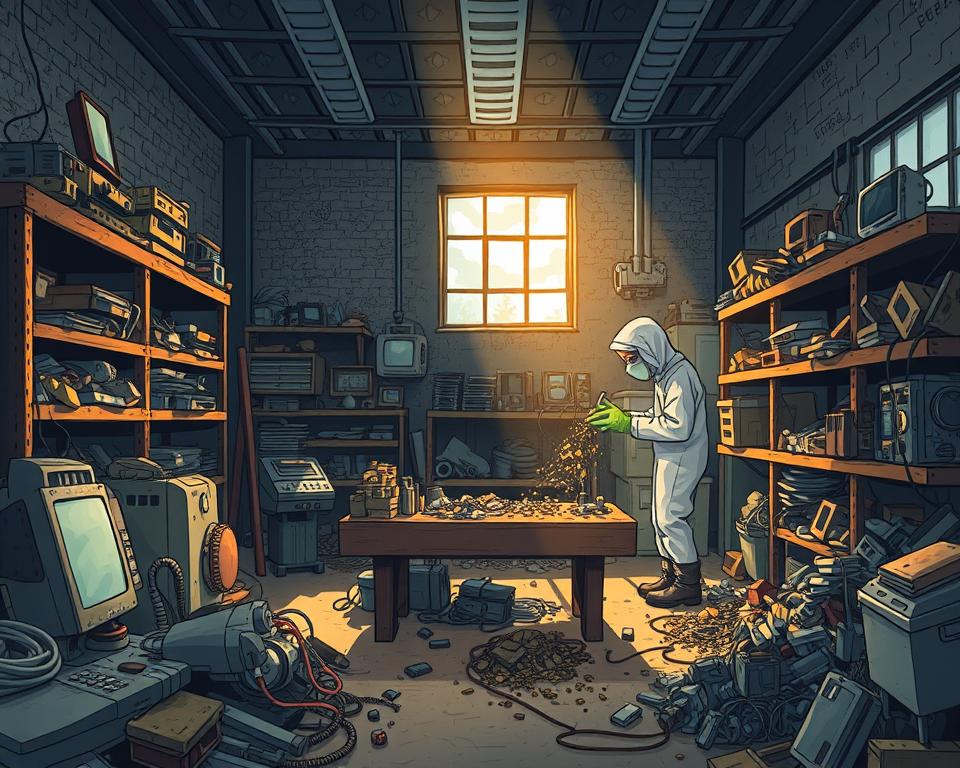

The Precious Metal Recycling Process

The precious metal recycling process is complex, involving several stages to ensure maximum efficiency. First, scrap electronics, jewelry, and industrial waste are gathered. Next comes sorting, cleaning, and testing to assess metal content and worth.

Recycling Workflow

A structured workflow is key to high-yield recovery. Every phase aims to maximize precious-metal returns. Sorting divides metals by kind and grade. Cleaning removes contaminants that could hinder recovery. Analysis identifies the concentration of precious metals, guiding the choice of recycling techniques.

Metal Separation Techniques

High-tech methods are used to maximize metal retrieval. Thermal reduction applies intense heat to isolate metals. Molten refining and wet-chemistry steps handle finer separations. Firms such as Dongsheng Metal Trading apply these techniques to raise recovery and profits.

Recyclable Precious Metals

Scrap recovery benefits both Earth and economy. A host of precious metals are recyclable, aiding markets and ecosystems. It’s important for people and businesses to know which metals can be recycled.

Recycling Gold, Silver & Platinum

Gold, silver, and platinum stand out among precious metals. You’ll see them in rings, currency, and industrial parts. Recycling gold is common due to its high value and demand. Silver recovery matters too, thanks to its role in imaging, tech, and solar.

Platinum, while rarer, finds value in catalytic converters.

Electronics Precious Metals

Electronic precious metals offer unique recycling chances. Gadgets—from phones to laptops—house palladium, indium, and more. These metals are a treasure trove for recycling, reducing e-waste and providing essential materials.

Recycling these electronics metals is imperative. Sectors strive to cut waste and boost recycling efficiency.

Industries that Benefit from Precious Metal Recycling

Metal recovery underpins major sectors by supplying reclaimed resources sustainably. Device manufacturing in electronics profits hugely from recovered metals. Aerospace and healthcare rely on them for vital parts. Examining industry recovery uncovers eco- and economic advantages.

Electronics Industry

The electronics industry leads in precious metal recycling due to the abundance of valuable metals in devices like smartphones and computers. Quick device turnover spawns more electronic scrap. Hence, recovering metals like gold, silver, and palladium is crucial. It preserves nature and lowers mining-driven CO₂ emissions.

Firms ramp up recycling to hit sustainability targets. That change bolsters resource saving and ecosafety.

High-Tech Industries

Recycling precious metals matters for aerospace and healthcare, given their reliance on them. High-performance alloys are essential for manufacturing flight parts and medical devices due to their durability and resistance to corrosion. Recovering them cuts costs and meets green regulations.

These sectors know green recovery eases resource shortages. And it improves operations, making metal recycling a smart green tactic.

Finding Precious Metal Recycling Companies

Choosing reputable metal recyclers is vital for success. Be sure to quiz them on their methods. Pricing models and processes make a big difference. Reviewing offerings lets you select wisely.

What to Ask a Recycler

- Can you share your precious-metal recovery accreditations?

- Can you explain your processing methods for different metals?

- Which recovery percentages do you achieve for each metal?

- Can you detail your fees and any surcharges?

- Do you have client testimonials or references?

Evaluating Offers

When searching for a recycler, it’s vital to compare different companies based on their services. Use a table to line up these factors:

| Company Name | Recovery Rate (%) | Processing Fee ($) | Turnaround Time (Days) |

|---|---|---|---|

| Recycling Co. A | 95 | 50 | 7 |

| Recycling Co. B | 90 | 45 | 5 |

| Recycling Co. C | 92 | 55 | 10 |

By comparing recycling services, you can find the best recycler for your needs. That way, you maximize returns and maintain quality.

Recycling Precious Metals: A Green Guide

Knowing recycler operations matters if you recycle metals. These experts manage the entire process, from collection to processing. That approach drives top efficiency and returns.

Recycler Operations

They apply high-tech processes—testing, sorting, refining—to recover metals. Collection comes from devices, jewelry, and industrial waste. Next, they employ precise methods to sort metals. Next, they refine these metals to extract precious elements like gold, silver, and platinum.

This process not only maximizes resource recovery but also supports eco-friendly practices. It’s fundamental to building a sustainable future.

Selecting Your Ideal Recycler

Key criteria matter when choosing a recycler. Start with their sustainability track record. In today’s market, a commitment to sustainability is essential. Also, consider the services they offer, from basic collection to full processing.

Your budget will influence your choice. Gather price quotes for side-by-side comparisons. Companies like Dongsheng Metal Trading offer customized solutions for various industries. They are a reliable choice for specific recycling needs.

The Role of Metal Recycling Facilities

Metal recycling is a critical sector for sustainable practices and waste management. It encompasses various recycling centers, each tailored to specific metal recovery needs. Understanding these facilities improves access to recyclers and their services. It aids companies and conserves nature.

Types of Facilities Available

There’s a broad spectrum of recycling operations. Certain centers specialize in high-value metals; others take general scrap. Here are a few common types:

- Scrap yards process a broad mix of metal types.

- Specialized firms recover gold, silver, and platinum with advanced refining.

- E-Waste Recycling Centers: Specialize in recovering metals from discarded electronics, capitalizing on the valuable components often found in these devices.

Facility Access Factors

Easy access to facilities boosts recovery efficiency. Firms need to plan transport logistics. Key access factors include:

| Factor | Description |

|---|---|

| Distance | Facilities located nearer to businesses minimize transportation costs and time. |

| Networking | Connections with nearby facilities speed up recycling. |

| Services Offered | Knowing each facility’s offerings guides your choice. |

Ultimately, facility type and access shape recycling success.

E-Waste Recycling & Metal Recovery

Discarded electronics threaten the environment. Old gadgets hide valuable metals ripe for recovery. It shows why we should treat e-waste as treasure.

Electronic Precious Metals

Devices often contain bits of gold, silver, and palladium. You’ll find them in components such as:

- Circuit boards

- Connectors and ports

- Capacitors and resistors

- Battery terminals

Common electronics conceal recoverable metals. By recycling, we retrieve and reuse these valuable elements.

E-Waste Recovery Benefits

Recovering e-waste metals safeguards the environment and reclaims materials. It trims dump loads and conserves raw materials. The benefits of recycling e-waste metals are clear:

- It lowers pollution risks tied to discarded electronics

- It curbs carbon footprints with sustainable recycling

- It bolsters circular models by returning scrap to production

Encouraging electronic recycling promotes sustainable resource management. It secures a healthier planet for tomorrow’s children.

The Future of Precious Metal Recycling

Recycling is changing fast thanks to new tech and eco-driven demand. As the need to conserve resources grows, major players in recycling are adapting. Adopting fresh techniques, they’re shaping tomorrow’s recycling.

Eco-Friendly Recycling Innovations

Current trends in sustainable recycling focus on reducing waste and minimizing environmental impact. Businesses adopt green packaging and energy-saving techniques. Such moves match worldwide green goals and nudge industries to be more eco-responsible.

Innovations in Precious Metal Recovery

Breakthroughs in recovery boost metal recycling yields. Robotic sorting and chemical extraction raise recovery. They boost recovery and cut environmental costs—a leap for metal recycling.

Launching a Metal Recycling Startup

Starting a precious metal recycling business demands meticulous planning and a deep grasp of operational and market dynamics. Entrepreneurs must outline key steps to build a strong foundation and adhere to industry regulations. That means in-depth market analysis and client identification. Also, obtaining necessary permits and understanding legal aspects is vital for sustained success.

Business Setup Steps

To launch your recycling venture, follow these steps:

- Analyze market demand and competitor landscape.

- Draft a strategy blueprint covering targets and methods.

- Invest in equipment tailored to your process needs.

- Raise startup funds through financing or investors.

- Get all required permits and licenses.

- Launch marketing to attract clientele.

Legal Considerations and Certifications

Knowing regulatory requirements is vital for a recycling startup. Meeting environmental rules protects your operation and the planet. Must-know compliance points:

- Securing business certification from relevant authorities.

- Ensuring full compliance with disposal and recycling laws.

- Ensuring all employees are trained on safety protocols and procedures.

As a Final Point

Precious metal recycling is essential for preserving natural resources and improving environmental health. It empowers all of us to reduce environmental harm from waste. Recovered metals curb mining and fuel green-job growth in recycling.

Metal recovery delivers both eco and economic upsides. Partnering with companies like Dongsheng Metal Trading ensures a commitment to eco-friendly practices. Such alliances reinforce the circular economy for all stakeholders.

A sustainable tomorrow hinges on our joint metal-recycling efforts. Increased awareness builds a culture of green consumption and care. Embracing these steps helps today and protects tomorrow’s world.