How to Identify Top Injection Molding Services in China

So, the big meeting just wrapped up. your new product has been approved, the timeline is aggressive, and the budget is, let’s say, constrained.. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

You nod, of course. It seems sensible at first glance. Savings can be substantial. Yet your thoughts are already spinning. You’ve heard all the horror stories, right? The quality disasters, the communication black holes, the shipment that shows up three months late looking nothing like the sample. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

But here’s the catch. Procuring China injection molding needn’t be a roll of the dice. It’s simply another project with clear steps. And like any project, it succeeds or fails based on the process you follow. It isn’t about the cheapest offer but about choosing the right supplier and running the process transparently. Forget the horror stories. Let’s go through a step-by-step guide to succeed.

Initial Step: Prepare Your Information

Before searching suppliers or opening Alibaba, nail down your requirements. In fact, most overseas manufacturing headaches stem from a vague or incomplete RFQ. You cannot expect overseas partners to interpret your unspoken requirements. It’s akin to asking someone to price-build “a structure” with no details. You’ll get wildly varied quotes that are useless.

Aim to craft an RFQ package so precise and comprehensive it leaves no room for error. This package is your project’s foundation.

What should you include?

Start with your 3D design files. They’re essential. Stick to universal formats like STEP or IGS to avoid any compatibility headaches. This is the master blueprint for your part’s geometry.

Yet 3D models don’t cover everything. Include precise 2D engineering drawings. This is where you call out the stuff that a 3D model can’t communicate. Think tolerances, material grades, finish specs, and any feature-critical notes. Call out smooth surfaces or precision hole sizes in big, bold notation.

Next up, material. Don’t just say “Plastic.” Even “ABS” alone is too vague. Get precise. Call out SABIC Cycolac MG38 (black), for example. Why be exact? Because plastic grades vary by the thousands. Naming the precise grade locks in the mechanical, thermal, and aesthetic properties you need with what is plastic mold.

A good supplier can suggest alternatives, but you need to give them a clear starting point.

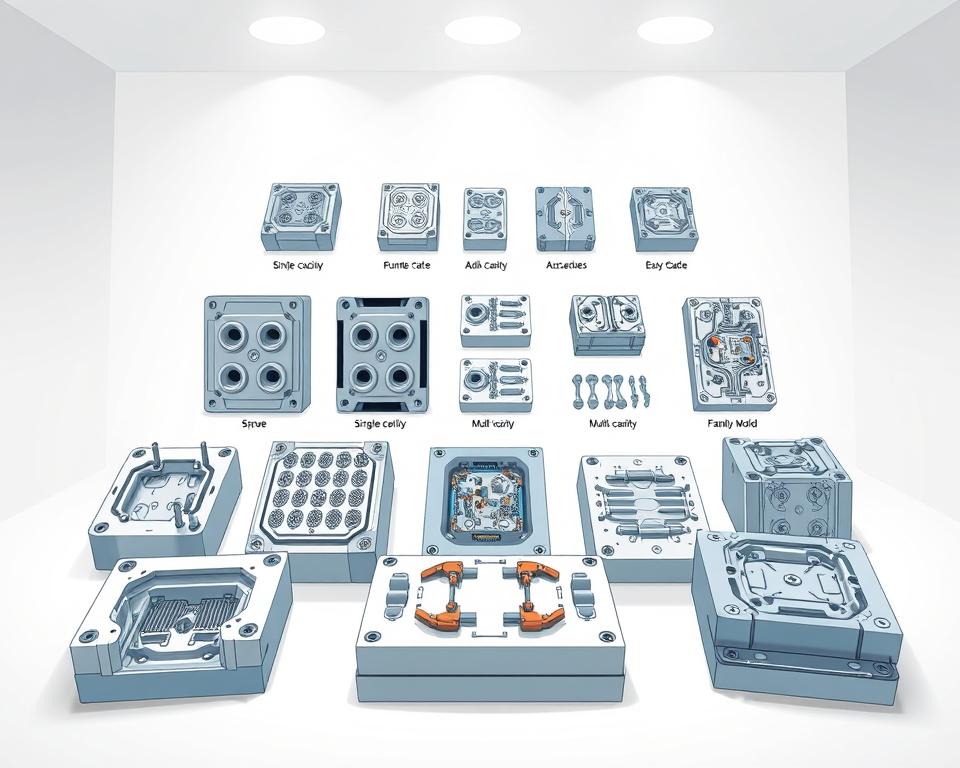

Finally, include the business details. What is your Estimated Annual Usage (EAU)? You must specify if it’s a 1K-part tool or a 1M-part production run. Tool style, cavity count, and unit cost are volume-driven.

The Great Supplier Hunt

Now that your RFQ is pristine. now, who do you send it to? The internet has made the world smaller, but it’s also made it a lot noisier. It’s easy to find a supplier; it’s hard to find a good one.

Begin on popular marketplaces such as Alibaba or Made-in-China. These are great for casting a wide net and getting a feel for the landscape. But think of them as a starting point, not the finish line. Narrow your pool to about a dozen promising firms.

But don’t stop there. Consider using a sourcing agent. Yes, they take a cut. But a good one has a vetted network of factories they trust. They bridge language and cultural gaps. On your first run, this is like insurance. Consider it timeline insurance.

Also consider trade fairs. If you have the travel budget, attending a major industry event like Chinaplas can be a game-changer. In-person meetings trump emails. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. Plus, ask peers for referrals. Tap your professional contacts. A solid referral can be more valuable than any ad.

Shortlisting Serious Suppliers

With your RFQ dispatched to dozens of firms, bids begin to arrive. You’ll see ridiculously low offers and steep quotes. Now, sift through and shortlist 2–3 reliable candidates.

How do you do that? It’s a bit of an art and a science.

Begin with responsiveness. Do they respond quickly and clearly? Do they communicate effectively in English? But the key: do they probe your RFQ? A great supplier will review your RFQ and come back with thoughts. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” This is a massive green flag. It proves their expertise and involvement. A supplier who just says “No problem” to everything is a walking red flag.

Afterward, verify their technical arsenal. Ask for a list of their equipment. Seek samples or case studies of comparable projects. A small-gear shop won’t cut it for a big housing.

Then comes the audit. You can’t skip this. You would never hire a critical employee without an interview, so why would you send tens of thousands of dollars for a tool to a company you’ve never truly vetted? You can travel or outsource a local inspector. They’ll send a local inspector to the factory for a day. They confirm legitimacy, audit ISO 9001, inspect equipment condition, and gauge the facility. That small investment can save you thousands.

From Digital File to Physical Part

You’ve selected your partner. you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Now the process kicks off.

The first thing you should get back after sending your payment is a DFM report. Design for Manufacturability (DFM) is essential. This is your supplier’s formal feedback on your part design. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. Comprehensive DFM equals a top-tier supplier. It’s a two-way partnership. You work with their engineers to refine the design for optimal production.

With DFM sign-off, toolmaking begins. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These represent the first trial parts. It’s your test of success.

Expect T1s to need tweaks. It’s par for the course. There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You’ll provide detailed feedback, they’ll make small adjustments (or “tweaks”) to the tool, and then they’ll send you T2 plastic mold in China samples. You may repeat this cycle a few times. Plan for this loop in your schedule.

Eventually, you will receive a part that is perfect. Dimensions, finish, and performance all check out. This becomes the “golden sample.” You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Crossing the Finish Line

Landing the golden sample is huge, yet the project continues. Now you’re entering the mass production phase. How do you ensure that the 10,000th part is just as good as the golden sample?

You need a clear Quality Control plan. Typically, this means a pre-shipment audit. Again, you can hire a third-party service. They’ll sample parts, check dimensions and finish versus your drawings and golden sample, and report. You receive a full report with images and measurements. Once you sign off, you greenlight shipping and the last payment. This simple step prevents you from receiving a container full of scrap metal.

Finally, think about logistics. Understand the shipping terms, or Incoterms. Does FOB apply, passing risk at the ship’s rail? Or EXW, where you handle everything from their gate? These choices hugely affect landed cost.

Overseas sourcing is a marathon. It’s about building a relationship with your supplier. See them as collaborators, not vendors. Open dialogue, trust, and rigorous procedure deliver results. No question, it’s demanding. But with this roadmap, you can succeed, achieve savings, and maintain quality. You’re set to succeed.